The success of Speltech has been built upon supplying bespoke solutions to our customer’s problems, whether it is sealing systems, abrasion and wear resistance, the movement of materials by air or friction, Speltech have provided solutions.

We have many years of experience and enjoy the challenge of working at the leading edge of product development, where we aim to deliver the right cost effective product on time.

If you would like to discuss your bespoke plans please don't hesitate to contact us.

-

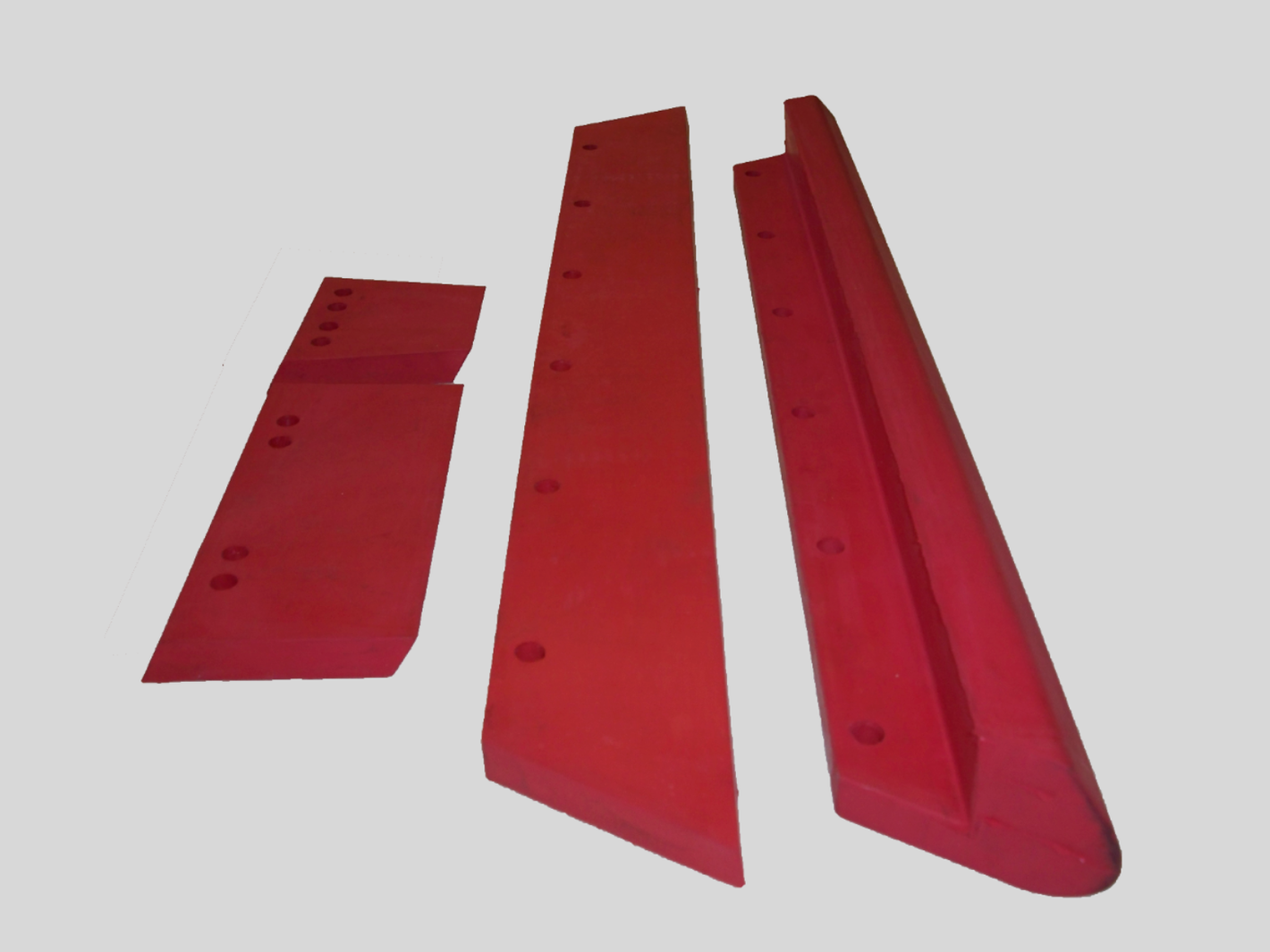

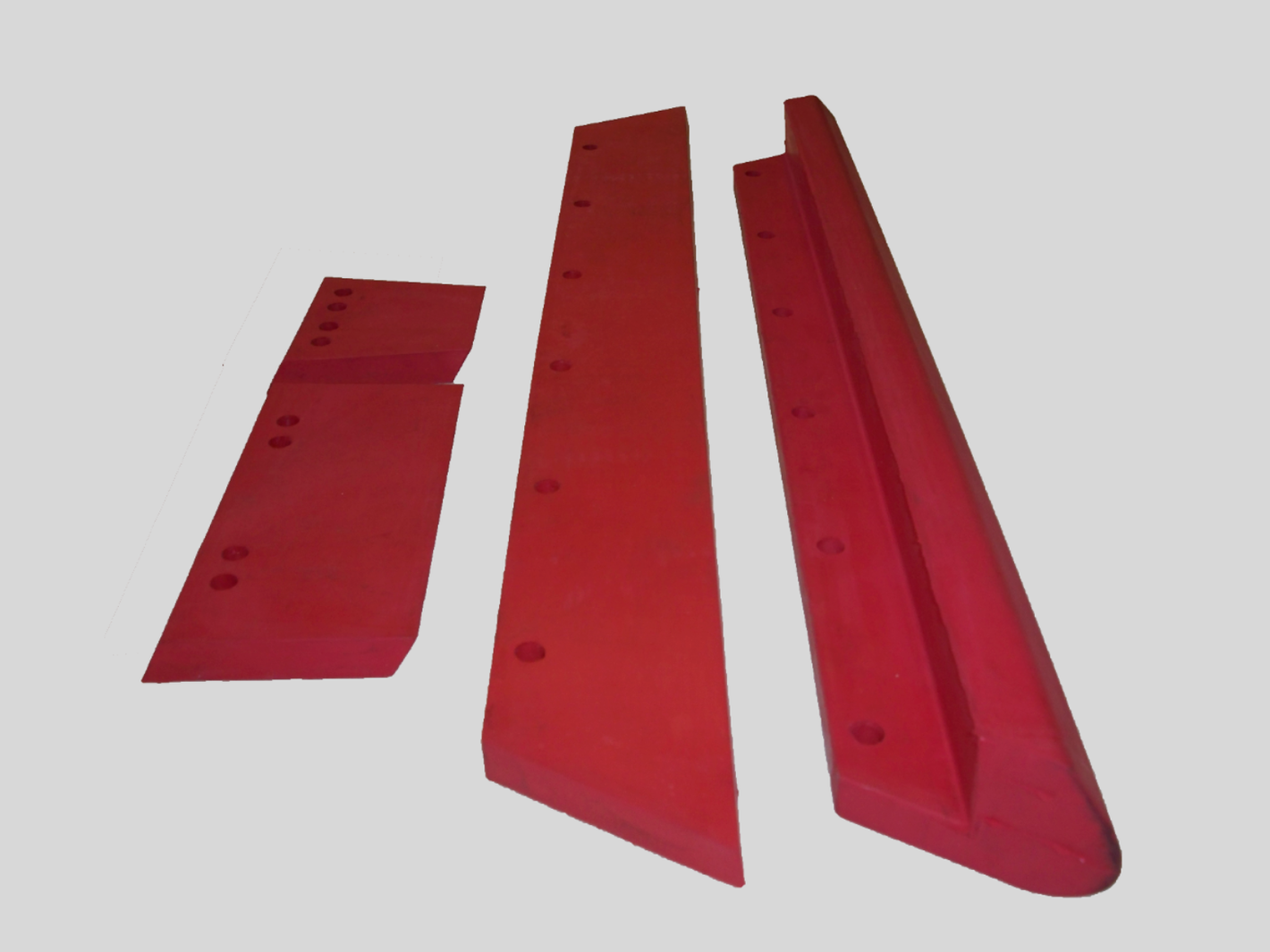

Rubber Fabrication

Cutting and forming rubber and other substrates to produce products which appear as extrusions or mouldings but with hidden qualities and little or no tool costs.

-

Compression Moulding

For larger parts or low volumes.

-

Transfer Moulding

Rubber to metal bonding, low- medium volumes.

-

Injection Moulding

High volume or intricate design, single or multi cavity, consistent quality.

-

Rubber Extrusion

Both solid and sponge materials.

-

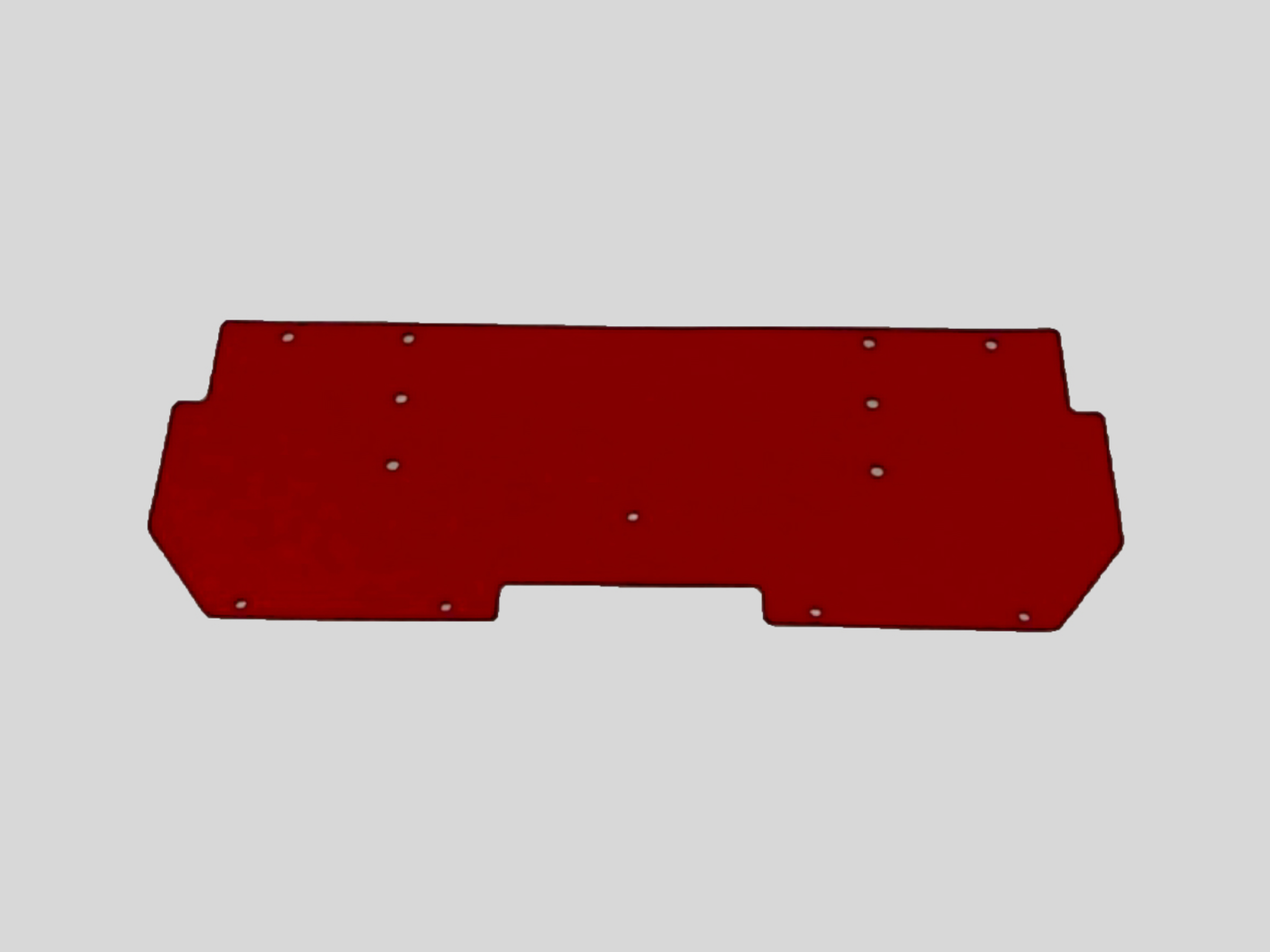

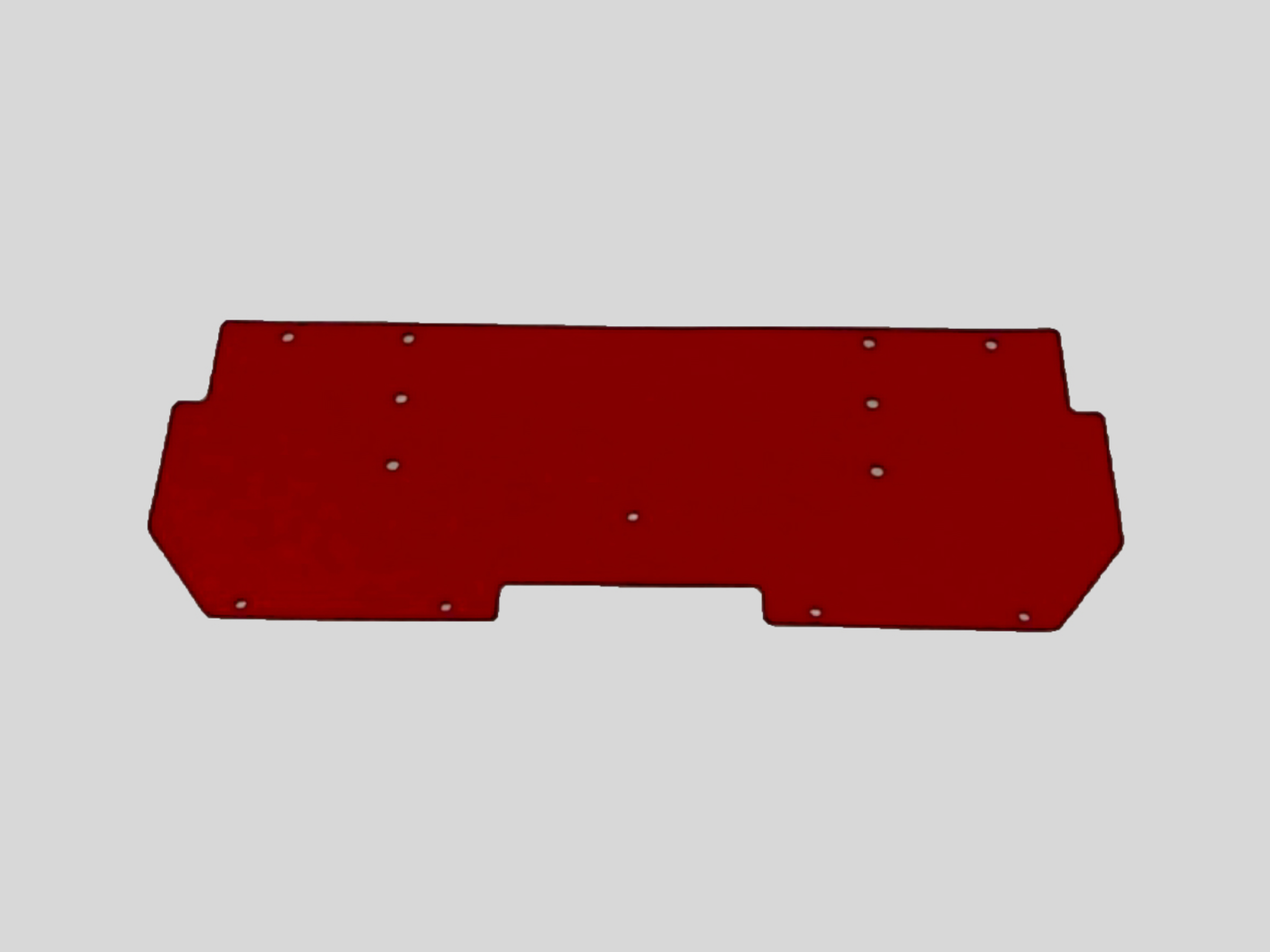

Water Jet Cutting

Water Jet Cutting enables the accurate cutting of intricate shapes from most solid and some sponge materials.

-

Die Cutting

Of solid and sponge materials, with or without self-adhesive backing.

-

Rubber to Metal Bonding

Rubber to metal / sponge rubber to solid rubber and inset mouldings and other substrates.